October 23, 2024

by: Benjamin Petrakis

HUGE ROI In 1 Year With Tracker

Tracker catches mistakes that cost pennies, but add up.

So you purchased a brand new half-million dollar state-of-the-art machine that gives you all the data right at the machine. You paid big bucks for this machine and the sales person guaranteed you it was a worthy investment with accurate data, so you take them at their word. That assumption could be costing you big time.

Here's a real-life scenario on how Tracker could have saved a company $750,000 in only 1 year. An operator noticed this error was occurring after years of it running, but Tracker could have caught it within minutes.

The customer runs extrusion machines making bags. The machines are set to cut and stack bags in packs of 25. The machines were actually stacking bags in packs of 26. No big deal - what's an extra bag, right? Wrong!

Let's do the math and see just how wrong that is. That machine makes a pack every minute, running 24/7, and the profit on a bag is $0.03.

$0.03 profit per bag x 60 packs an hour = $1.80 given away in per hour.

$1.80 x 24 hours = $43.20 given away per day.

$43.20 x 365 days = $15,768 given away annually, on only 1 machine.

Tracker would have paid for itself in 1 year, monitoring only 1 machine. Now, you hook up all 48 lines and catch the same error.

$15,768 x 48 machines = $756,864 given away annually because your state-of-the-art machines put 1 extra bag in each pack.

Mistakes, errors, downtimes and inefficiencies only cost pennies when they happen, but over time those pennies add up quickly.

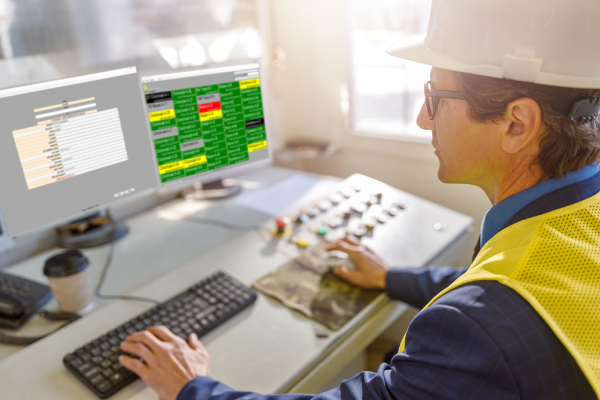

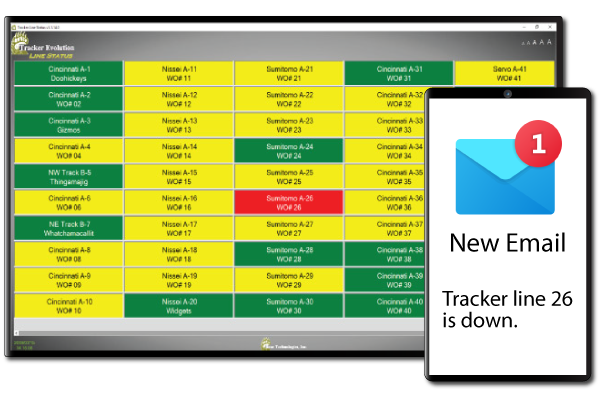

Tracker gives you real time data down to the hundredth of a second, accurate part counts and immediate alerts to downtime events. Now, do the math on what Tracker could save you shaving 2 minutes off your downtimes each year.

Recent Newsletters

- Happy holidays and merry Christmas January 6, 2022

- Times like this demand increased machine efficiency October 3, 2024

- No monthly or annual subscription fees

- No annual license renewal fees or contracts

- Free software updates and US-based tech support

- Free virtual training sessions

- Employ a Tracker June 23, 2022

- Tracker update - Evolution Express November 8, 2019

- Production monitoring that won't blow your budget January 14, 2025

- No monthly or annual subscription fees

- No annual license renewal fees or contracts

- Free software updates and US-based tech support

- Free virtual training sessions

- Real-Time Quick Edit Feature Added May 3, 2023

- Labor shortage? Here’s your solution. September 30, 2021

- A machine goes down

- A job is on schedule to close during the current shift

- A scheduled PM is occurring during the current shift

- A machine efficiency has dropped below a certain threshold

- Program your own shift-based alerts

- Upgrade Your Tracker Software Today February 26, 2025

- Take advantage of 10 percent off October 4, 2021

- No subscription fees

- No annual license fees

- Free lifetime software updates

- Free lifetime tech support 7 days a week

- Above prices are with 10% discount applied

- Production Monitoring, Simplified October 12, 2022

- HUGE ROI in 1 year with Tracker October 23, 2024

- Production monitoring under $10k - all in October 1, 2019

- Best value production monitoring system since 1991 May 2, 2022

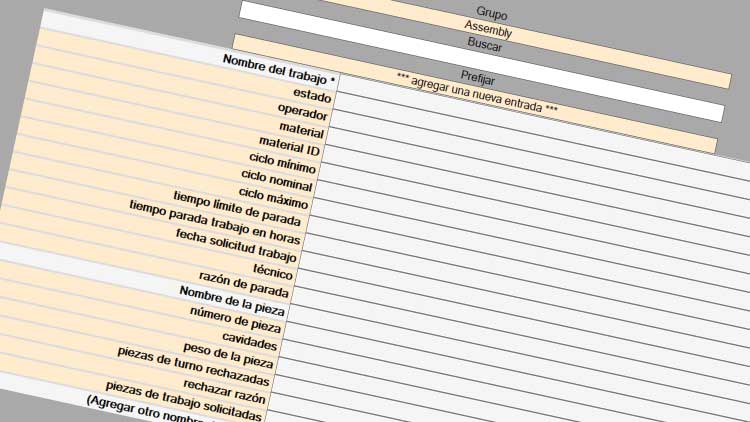

- New Feature Release - Language Translation March 1, 2023

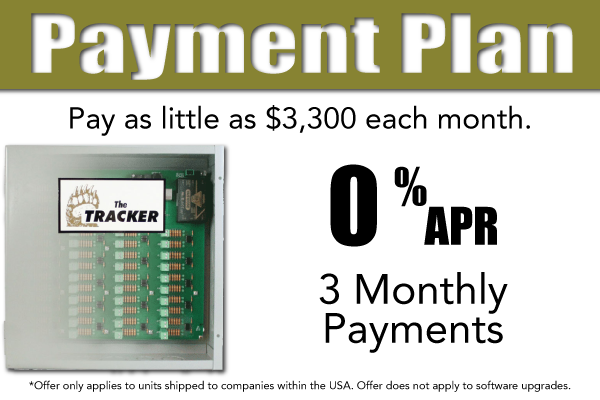

- Payment Plan Now Available April 4, 2022

- You get what you pay for June 16, 2022

- Text Notifications March 2, 2022

- Eliminate Plantnode 360 subscription fees February 14, 2020

- Happy 30th anniversary! November 29, 2021

- Best ROI on the Market June 6, 2022

- Eliminate machine monitoring fees September 22, 2021

- Important software update January 3, 2022

- Download the processor application.

- Stop the current processor.

- COPY the new application over the old one - DO NOT move the file.

- Reopen the processor and you are all updated.

- Free virtual demos August 24, 2021

Benjamin Petrakis

These have been very trying times for not just our industry, but our communities, our country and throughout our entire planet. While we are spending time with our families and loved ones during this time of year please take some time to be thankful for all we have. Too often we take things and people for granted with the assumption that they will always be there.

To anyone who has lost employment or had to close their doors for whatever reason, we hope you land on your feet and hit the ground running with enormous success. To anyone who has suffered loss of a loved one, you have our deepest condolences and we pray you find peace and acceptance. To anyone that is just plain struggling with a situation that weighs heavy on your heart, we hope you find the strength to overcome it and smile again.

We are all in this crazy complex thing called life together - all of us as brothers and sisters of humanity. Smile more, laugh more, thank a veteran or active servicemember of the military, law enforcement or first responder, tip your bartender and waitstaff, donate to charity if you are fortunate enough to be able to, hold the door for someone, let the little old lady behind you in line just getting milk go first. It does not take much to be a kind human, but kindness is contagious and the little ones are watching us "elders" and learning.

We wish you all happy holidays, a very merry Christmas and a happy New Year.

Benjamin Petrakis

As the world burns around us, entire communities are washed away or under water and our supplies are being held hostage - this is the time to make the most out of what you have available, and at the price you paid for them today because tomorrow they will cost more.

Tracker is the most affordable, reliable and flexible way to monitor your production operations for inefficiencies. Get instant notifications of downtimes, hold every employee on every shift accountable and easily pin-point problem trends.

Monitor up to 48 machines for only $15,500. Tracker is scalable to meet any needs - from 1 machine to over 1,000. View data anywhere throughout your entire network, even across state lines.

Benjamin Petrakis

Looking to gain an advantage while the cost of everything is rising? Employ a Tracker. Before you say we don’t have the capital right now and carry on to find new hires, let me explain the roles and duties they assume.

A Tracker plays several different roles in your business. They walk around with a stopwatch to all your machines and record cycle times accurate to the 1,000th of a second. They send real-time email and text alerts to the personnel on staff for anything worthy of being notified about. They crunch the numbers to tell you if a job is going to finish on time, when the estimated end time is, how much material a job will require, what the current part count is and many other stats. They input all the data from every machine and job into an Access Database every five minutes. They send all your machine data up to the cloud so you can see it from anywhere in the world on your mobile devices. They can produce reports as quick as you can tell them what you want the report on. All the while keeping you informed, in real time of each machines cycle status in a quick-reference color-coded format.

They do this 24/7 for as long as you keep them employed. Tracker’s do not require any time off or sick days and will never search for employment anywhere else, they are very loyal. There are no benefits or 401K required and they have 30+ years experience in the plastics manufacturing industry. What would that employee be worth?

$10,000 will get a Tracker to run between up to 16 machines, and $15,500 will get a Tracker capable of running between up to 48 machines – those are one-time payments, not an annual salary. You can have as many employed as you have the need for. They are very small and never seen on the shop floor, so OSHA and the Fire Marshall cannot count them against you as present bodies and they will not get in the way of other employees. Trackers can also be taught new skills and we pick up the tab on their education for life.

We have several Trackers seeking employment today and can have them on your doorstep in 2 days with their steel toe boots on ready to work. Give us a call today! (833) 232-7832

Benjamin Petrakis

You asked and we answered - we have had several requests for the new Tracker software upgrade to look and function more like their current version 4 software to reduce the learning curve. So we created the perfect marriage of Tracker version 4 and Tracker Evolution - Tracker Evolution Express.

Tracker Evolution Express was built by simplifying Tracker Evolutions advanced data processing and putting it in a unified Tracker version 4 theme. This will greatly help reduce the learning curve for the companies already running a Bear Tracker system.

Evolution and Evolution Express are included in the same program package and run concurrently so each user can choose their own flavor of Tracker to run. The floor can run Evolution Express for need-to-know information, while management utilizes the full power of Evolution for analyzing and reporting.

And yes, there are still shift notes in Tracker Evolution Express.

Benjamin Petrakis

Before you spend tens of thousands of dollars of your yearly budget on a system to help increase efficiency and streamline your operations, consider spending a fraction of that and accomplish the same goals, if not more.

The Tracker production monitoring system is the perfect solution for real time downtime alerting on a budget. Whether you run 1 machine or 1,000 machines, lights-out operation or staffed 24/7 Tracker will immediately alert you to every downtime event so you can respond quicker and get back to making money.

Tracker is not just a downtime alerting system - it has many other features that help to increase your efficiencies and meet your goals, and we have yet to find another system that can even come close to our pricing.

Tracker is the most affordable, reliable and flexible way to monitor your production for inefficiencies. Get instant notifications of downtimes, hold every employee on every shift accountable and easily pin-point problem trends.

Monitor up to 48 machines for only $15,500. Tracker is scalable to meet any needs - from 1 machine to over 1,000. View data anywhere throughout your entire network, even across state lines.

Benjamin Petrakis

Removing even one click from a task is a very noticeable difference, as silly as that sounds if you think about how long it takes to click once. If you eliminate several clicks, now you\

Benjamin Petrakis

Labor shortages and increasing cost of materials has made it more important than ever to know exactly what’s happening on your plant floor. Tracker will alert you to inefficient or down machines on workstations and plant floor overhead monitors, and via our shift-based email alert program.

Get email alerts when:

Benjamin Petrakis

Tracker version 4, due to the age of the software has been set to legacy and can no longer be supported with technical support. This software version, released in 1992 was everything plastics molders needed to know to increase efficiency and minimize downtimes.

Times have changed, and so has our software - our new Tracker Evolution software was built with extreme flexibility in mind. We included most, if not all of the customizations we did to customers version 4 software, added a slew of new features that customers mentioned they would like to see, and kept the same version 4 theme to minimize the learning curve.

Upgrading is quick and painless - it usually takes less than 30 minutes. All of your machine names and job presets are easily transferred over and there is no rewiring necessary. The software is only installed on the host PC/server and shared to all the workstations over your network, so there is no need to install a workstation software anymore and updates are automatically applied to workstations when the host is updated.

We can hop on a Microsoft Teams meeting and walk you through everything from downloading the software to getting it set up and training your team on all the new features.

For all the companies that are already running Tracker Evolution, please take a moment to check our downloads page and verify your software applications are up-to-date so you are sure to take advantage of the new features we periodically add. The software updates are free-of-charge for all current Tracker Evolution users.

Benjamin Petrakis

We currently offer a 10% discount on all units and software applied to all prepaid POs and website purchases. Take advantage before we discontinue the offer on January 1, 2022.

Benjamin Petrakis

When you think of production monitoring systems, do you think of having to analyze data to get any use or benefit out of it? This could not be further from the truth. Sure it helps with fine tuning, but the real value being produced is instant notifications of downtime. The quicker you fix a down machine, the quicker you are back to printing money.

Tracker got its start in 1991 targeting the smaller plants that didn\

Benjamin Petrakis

So you purchased a brand new half-million dollar state-of-the-art machine that gives you all the data right at the machine. You paid big bucks for this machine and the sales person guaranteed you it was a worthy investment with accurate data, so you take them at their word. That assumption could be costing you big time.

Here\

Benjamin Petrakis

• Ease scheduling duties

• Use machines more effectively

• Engage all employees in plant efficiency

• Unite departments with real-time job, production, and machine status

• Quickly pin point trouble areas

• Expedite delivery of a better quality product to your customers

• Increase sales

• Reduce waste

• Comply with "Lean Manufacturing" standards

• Increase your OEE performance

See your present to ensure your future.

• Monitors almost all types of machines - old and new.

• Fully customizable fields and calculations.

• Real-time mobile device access.

• Real-time shift-based email alerts.

• (2) Built in Access databases.

• Edit historical data for accurate real-time information.

• Build custom reports for quick and accurate reporting.

• Cross compare custom reports on screen and export to .CSV file.

• Independently display multiple group windows simultaneously.

• Text files make for easy ERP and MRP integration.

• Quick, easy network installation.

Benjamin Petrakis

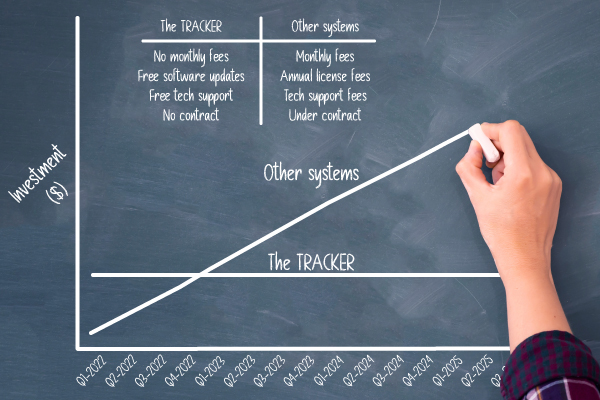

Bear Technologies was founded in 1991 developing Tracker to cater to the smaller businesses, the “mom and pop shops” that couldn’t warrant the hefty price tag, monthly payments and additional fees that come with almost all production monitoring systems on the market.

We made a product that gave companies all the same data at a fraction of the cost of the bigger name brands, with no subscriptions or recurring fees and even allowing spacing the system cost out over 3 months. We didn’t stop at making it affordable - we sweetened the deal with free lifetime software updates and free tech support 7 days a week.

The math was, and continues to be simple – some companies pay what a complete Tracker system costs in only 3 months with their monthly subscription fees. We have customers that are still running the same system they purchased 30 years ago and haven’t had to make a single payment to keep it running. When you deal with a small business you get perks that may not be made available by the larger corporations.

Our level II tech support wizard wrote the source code for the program – he knows all the ins-and-outs and can quickly deal with any issue presented. Each Tracker unit is hand-assembled and goes through thorough hand-testing of each input and output before it gets the Tracker sticker put on it. From the design of the circuit board to the choice of components we use, we have built this system to last.

In the beginning we were only able to effectively monitor in the injection and blow molding industries with fixed matrixes, only 1 department and limited to 288 inputs. In 2018 we changed that with the release of our Tracker Evolution software that can effectively monitor any industry that creates a high/low or on/off signal in their part production and allows for user-edited custom matrixes for each process they have with no input limitation, making Tracker available to all companies big and small.

This has been a 30 year journey to reach as many small businesses as we can to help them increase their profits, and it’s been a fun ride so far.

Benjamin Petrakis

Fun fact - only half of the world\

Benjamin Petrakis

We understand times can be really tough on your wallet right now so we have decided to offer a payment plan on all new system purchases. Split your payments up equally over 3 months with 0% APR. Get up and running for as little as $3,300 down, then 2 more monthly payments after that.

Benjamin Petrakis

In life you learn that you pretty much get what you pay for. If you decide to go the more cost-effective route there will be negative consequences, like life span or accuracy of the product. This is generally a good rule of thumb, but like most rules there are those exceptions.

When it comes to investments, people usually do their research and cost is usually a major decision-making factor. Most want the best option available at a fair cost to them, quickly eliminating the options that have a price point out of their reach and far below the average market price – because nobody wants to consider neither the option they cannot have nor the “cheap junk” which, in their mind will probably make for nothing other than a paperweight in a month. The thought process of eliminating the highest and lowest cost options is usually a safe bet when doing quick research and only factoring price for a short-term investment like a TV or headphones, but it isn’t the best tactic when considering a long-term investment.

Cost should be just one of the many factors analyzed when considering a long-term investment. Take the time to learn about the company – they might have an extremely low overhead which is reflected in their below market price. Assess all the features of the individual options – sometimes the cheaper option will give you even more usable features than the most expensive. What does their post-sale support record look like - are they a company that cares to know how they are benefiting you or inquire about how they can improve to better serve you? Who handles their post-sale support - is it in-house support or outsourced to the cheapest bidder with a pre-written script to follow when you contact them, and what do those support queries cost you? What options lock you into a contract requiring a monthly payment for services, and what could those payments amount to over time? What does the potential ROI look like? What do other first-hand consumers have to say about the options?

Before you automatically disregard an option based solely on the price tag, take the time to fully understand the who, what, where, when and how of that option. The one that you would strike-through first might actually be your best option of them all.

Benjamin Petrakis

Now you can receive a text message alert if a machine goes down, Tracker goes down or any other notification you choose to create within our shift-based email alert program. Simply add an email with the phone number and the carrier MMS gateway.

Below is a link to an article with the different carriers gateways. Make sure to use your carriers MMS gateway to ensure delivery of the text message.

UPDATE: Since the first quarter of 2024 most cell carriers discontinued the ability to use this feature due to the increasing amount of spam messages being sent using this method of communication. Please verify that your cell carrier allows for this before proceeding to use it in the Tracker Alerts program.

https://www.digitaltrends.com/mobile/how-to-send-a-text-from-your-email-account/

Benjamin Petrakis

Uses the same hardware interface box

No rewiring necessary

No monthly subscription fees

No annual licensing fees

No contract

More data capabilities

Award-worthy 7 day tech support

Tracker Evolution software - $4,900

• Easily tailor your system to your operation and reporting needs.

• Customize reports to match your MRP or ERP system for easy integration.

• Add custom fields with calculations and delete the ones you will not use.

• Create infinite machine departments with their own fields, calculations, and reports.

• Build a custom Access database file while another file is constantly updating all of your data.

• Get shift-based email alerts for downtime events, and create your own alerts with contact groups.

• Real time mobile access to your line status and line summary data.

• Tracker software is only installed onto one PC or server, and shared over your network.

Benjamin Petrakis

Thank you to all of our customers that have believed in our system and supported us throughout these 3 decades. Without you this would not have been possible. We appreciate each and every one of you! Cheers, and here is to another 30 years.

Benjamin Petrakis

The math was, and continues to be simple – some companies pay what a complete Tracker production monitoring system costs in only 3 months with their monthly subscription fees. We have customers that are still running the same system they purchased 30 years ago and haven’t had to make a single payment to keep it running - providing continuous growth on their ROI.

With the introduction of our 3 month extended payment option available to US residents, you can now monitor up to 48 inputs for just about what a monthly subscription plan would charge you each month. The best part about Tracker is that the payments actually stop after 3 months which allow you to stack that money into your ROI. As an added bonus, we also include free software updates and in-house technical support for life.

Tracker has the same data, accessibility and reporting capabilities as the other subscription plan systems, plus some you will not find anywhere else. Bear Technologies, Inc. leads the way in affordable production monitoring that meets the demand of any company large or small, domestic or foreign.

We are here to help you run more efficiently and save money. Give us a call today to see how we can assist you in reaching those goals. (833) 232-7832

Benjamin Petrakis

If your production monitoring system is subscription-based then you are paying way too much. Paying per line, per month with update fees and any other hidden fees can add up to over $50,000 per year in some instances.

$15,500 will monitor 48 lines for as long as you own the Tracker monitoring system, and in most cases provide you with better data and more features. We even throw in free lifetime software updates and free tech support 7 days a week. Have more than 48 machines? No problem, link as many Tracker units together as you have a need for.

Contact us today to find out how much you could save!

Benjamin Petrakis

We have made dramatic changes to our Tracker processor. To take advantage of the new increased speed, usability features and several other minor bug fixes click the link below for an instant download of the new processor software.

To update the processor:

Benjamin Petrakis

With COVID still remaining a thorn in our sides, the easiest way around all the safety protocols is offering virtual demos. This way everyone is guaranteed to remain 6 feet apart and nobody has to worry about face masks, or what part of the country everyone is from.

Simply schedule a demo for a time that works for you and your team, and we will meet you on the web to show you exactly why the Tracker is the best monitoring system for your company.

Rochester, NY 14612